Solving Ergonomic Issues in a Manufacturing Process

Our client specialized in managing beehives and harvesting honey.

As part of their operations, they faced a hazardous step in the honey harvesting process (pouring 60 pound buckets of honey into a funnel 7 feet tall), which our team was tasked with addressing and improving.

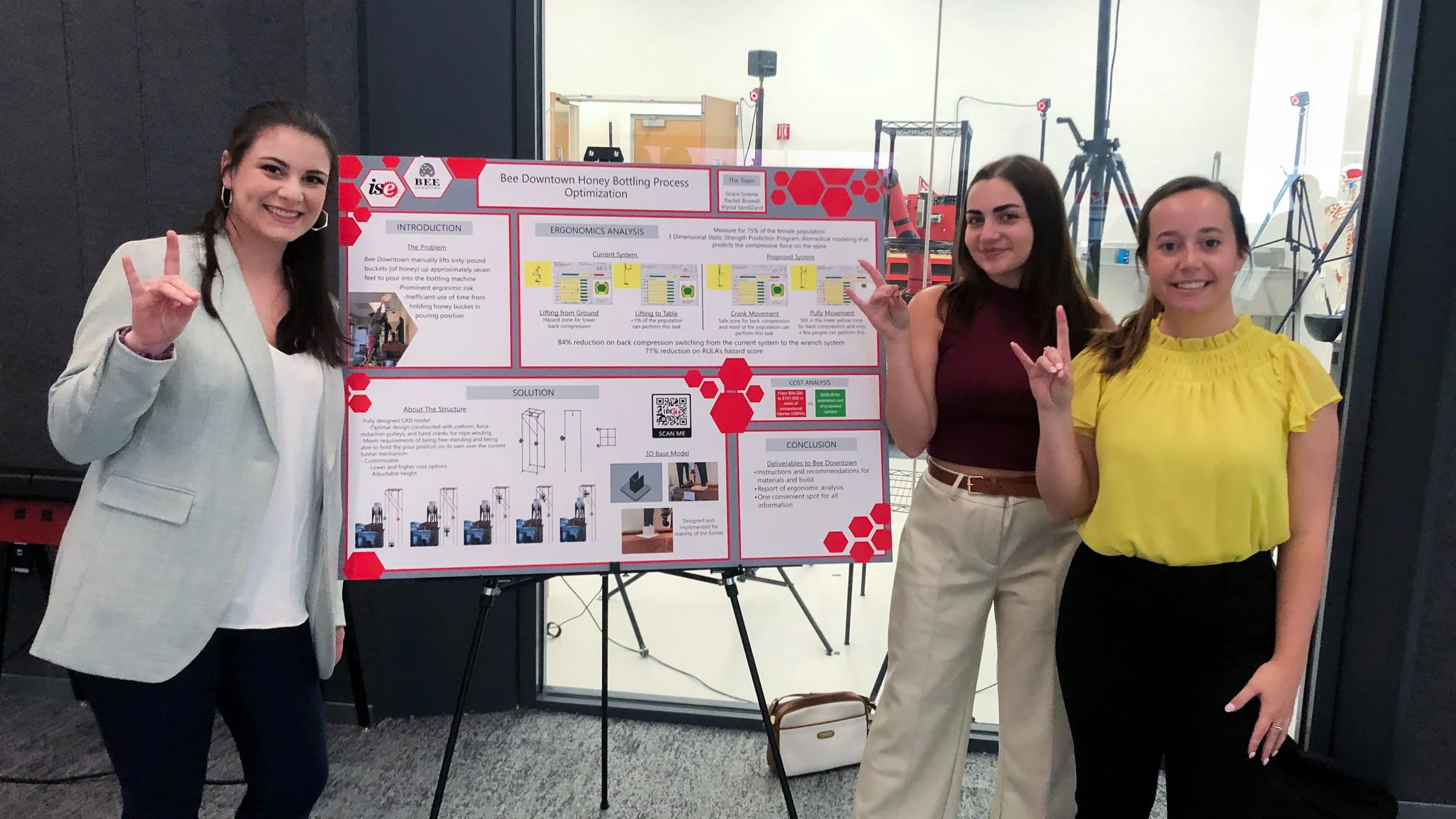

Team

Alyssa SaidiZand | Rachel Boswell | Gray Green

Problem

Unstable bottling system

Physical pain and accessibility issues

Prominent ergonomic risks

Inefficient use of time

Solution

Design a new bottling system that is ergonomic, accessible and time efficient

Enable a broader range of users for this manufacturing process

Provide safety tips

84% Reduction in Back Strain

3rd place overall

Outcomes

Ergonomic Impact

Removed manual lifting of 60 pound buckets into a 7 foot tall funnel

$157,000+ in Potential Injury Costs Avoided

Minimized risk of workplace injuries and related expenses

Accessibility Compliant Redesign

Environment adjusted to meet universal accessibility standards

Injury Prevention Measures Implemented

Reduced risk of cumulative trauma disorders through improved workflow and posture alignment

Competition Recognition

1st place - Industrial Engineering Design Competiton

Awarded for innovation and impact in ergonomic workplace design

Represented at IISE Conference | Seattle, May 2022

Selected to present and compete internationally

Among top teams across the Americas

My Role

With a background in human factors, I focused on testing the physical strain on the body both before and after implementing our solution using the 3DSSPP software. Given our small team size, most tasks were collaborative, but I led the efforts in ergonomic mechanics and human-centered design.

Research and data analysis

Software learning and application

Ergonomic design and testing

3D modeling

Human interaction design

Accessibility checks

Creative problem solving (including project pivots)

Project planning and management

Collaboration with stakeholders, team members, and mentors

Documentation and deliverables

Responsibilities

Read about the process:

-

We began by gathering all relevant information through research, focusing on the ergonomic challenges and constraints.

Conversations: Engaged with stakeholders to identify challenges, requirements, constraints, and needs.

Environmental Analysis: Assessed potential hazards, such as the unstable bottling system stand.

Customer Journey Analysis: Mapped out every step of the task to ensure comprehensive problem-solving.Measurements & Photos: Collected data for input into testing software.

Testing the Current Process: Used the 3D Static Strength Prediction Program (3DSSPP) to assess the load on the body.

Target Population: Designed for 75% of the female population, ensuring accessibility for the majority.

-

We brainstormed various designs, iterated on them, and tested the concepts using software to ensure our solution minimized ergonomic strain and truly enhanced the system.

Requirements: Developed a system to remove strain from the body and safely pour honey buckets into the bottling system.

Brainstorming: Collaborated with mechanical engineers to design a structure using their expertise.

Testing & Iteration: Continuously tested and refined our design to meet ergonomic and safety requirements.

Final Design: Created a fully developed CAD model using Creform, force reduction pulleys, and hand cranks for rope winding. The design was free-standing, capable of holding the pour position, and customizable with adjustable height for enhanced accessibility.

-

Despite budget constraints that prevented full construction, we delivered:

A custom 3D printed stand to stabilize the bottling machine.

A comprehensive CAD model and detailed instructions for building the system.

An analysis report detailing physical and monetary savings from our proposed system.

-

While constraints prevented us from fully developing the system, our work laid the foundation for a safer and more efficient process.